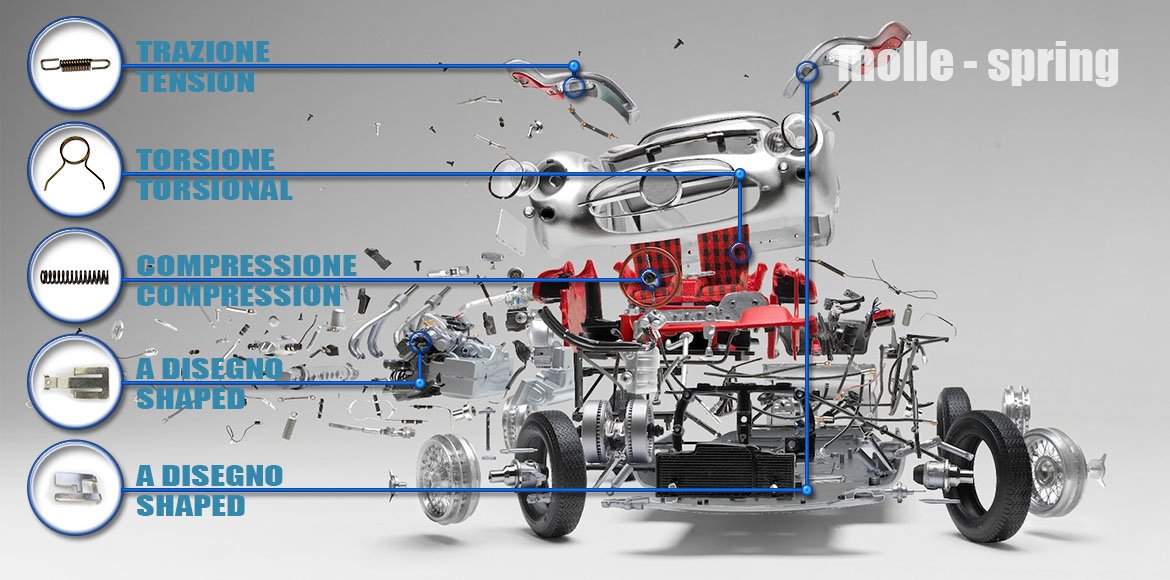

In every device used today, from cars to household appliances, springs provide functions that make our lives easier without being visible to the user.

b&m customers are companies from all industries – but mainly automotive and supply industry;

Our area of operations include wire and metal sheet springs;

The used materials are according to standards of the automotive industry;

Processed are spring steel wire and spring band steel according to DIN EN 10270-1 DIN EN 10270-2 and DIN EN 10270-3 as well as iron, non-ferrous metals as copper, bronze, CuBe, Ms and special materials

Key aspects are quality, functional requirements and cost efficiency;

According to requirements (sunroof, seat or auxiliary heating system, etc.) shape, material and surface can vary.

Compression springs

Spring geometry can be cylindrical, conical or barrel-shaped;

Compression springs are made from round or square shaped wire;

Closed, or closed and ground spring ends;

Wire diameter: from 0.1mm – 5.0mm.

Tension springs

Tension springs usually have a cylindrical form;

Eyes according to the standard DIN 2097 but also special eyes are possible;

Tension springs are made from round shaped wire;

Wire diameter: from 0.1mm – 5.0mm.

Torsional springs / Moulded wire parts

The spring geometry is adjusted depending on the area of application;

Spring loading occurs by torsion around the axial direction;

Torsion springs are made from round or square shaped wire;

Wire diameter: from 0.1mm – 5.0mm.

Shaped springs

The shape of the spring is developed depending on the area of application;

Shaped springs are made from spring band steel;

Sheet metal: from 0.1 mm – 3.0 mm.